metalbender

Assistant Cook

- Joined

- Nov 14, 2009

- Messages

- 8

hi all! new here, was hoping to get some feedback on folks with a passion for cooking.

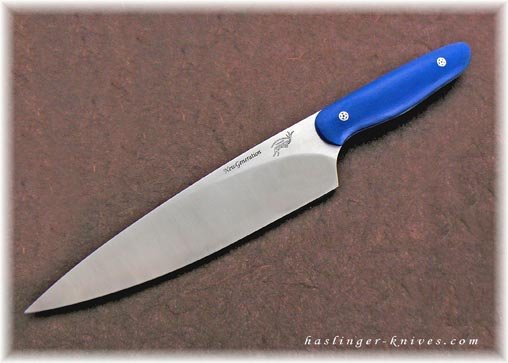

this is a custom order I recently finished and it got me to thinking about making sets as I enjoyed the divergence from hunters and bowies and camp knives.

the knife is 1095 H.C. steel, differentially heat treated and tempered back to a blue instead of the usual bronze,

over all length is 15 1/2 inches with the blade at 9 inches in length. at its widest part it is 1 3/4 inches wide. it is 3/16s thick at the spine and has a convex edge geometry.

handle material is stabilized Bubinga wood pinned with brass with the bolster being nickel silver also pinned in brass. also some copper spacers betwixt the bolster and scales for that added bling

so what do you all think? Im thinking about doing a full chef's set and bringing it to my local culinary supply store on consignment, the set will likely be in the 1500-2k range. whats everyone's thoughts? there a market for custom made hand forged kitchen sets?

thanks for looking and any feedback!

Shane

this is a custom order I recently finished and it got me to thinking about making sets as I enjoyed the divergence from hunters and bowies and camp knives.

the knife is 1095 H.C. steel, differentially heat treated and tempered back to a blue instead of the usual bronze,

over all length is 15 1/2 inches with the blade at 9 inches in length. at its widest part it is 1 3/4 inches wide. it is 3/16s thick at the spine and has a convex edge geometry.

handle material is stabilized Bubinga wood pinned with brass with the bolster being nickel silver also pinned in brass. also some copper spacers betwixt the bolster and scales for that added bling

so what do you all think? Im thinking about doing a full chef's set and bringing it to my local culinary supply store on consignment, the set will likely be in the 1500-2k range. whats everyone's thoughts? there a market for custom made hand forged kitchen sets?

thanks for looking and any feedback!

Shane